Environmental management

SMPC’s environmental management is part of the overall management approach encompassing ‘Sustainability in Environmental Dimension’. It serves as a demonstration of the company’s commitment to effectively manage business groups, functions, and operational areas in alignment, with a primary focus on sustainable management.

Sustainability Management in the Environment Dimension

Environmental Policy and Practices

To protect the environment, the company has adhered to an environmental policy consisting of the following objectives:

1.

Create a process that is consistent with international management systems, ensuring that all sectors involved in work and production processes are environmentally friendly, prioritize product quality, adhere to legal standards, and provide exceptional service.

2.

Minimize losses through cost-reduction systems and damage prevention to enhance the quality and productivity of products. Commit to continuously developing and improving quality management systems and environmental performance.

3.

Respond promptly and efficiently to incidents impacting the environment and the community due to the company’s operations, fully cooperating with government officials and relevant agencies.

4.

Commit to complying with laws and other requirements relevant to the organization’s context.

5.

Dedicate to developing, responsibly managing, and upholding environmental care, as well as respecting local customs and traditions where the company operates. Refrain from any actions that could harm natural resources and the environment, aiming to protect the environment, prevent pollution, and maximize the benefits of natural resources.

6.

Prevent accidents and control waste emissions to stay below acceptable standard levels or legal requirements.

7.

Promote environmental management awareness among organizational personnel.

8.

Cultivate personnel in the organization to be conscious of quality, environment and safety.

Performance

The company acknowledges that conducting business with environmental friendliness is one of the key factors for sustainability. In order to meet international standards and gain global recognition, SMPC has implemented a policy to encourage employees to efficiently utilize resources such as electricity, water, and oil, and appropriately control their usage. Since 2017, the company has been accredited with ISO 14001:2015 — Environmental Management Systems.

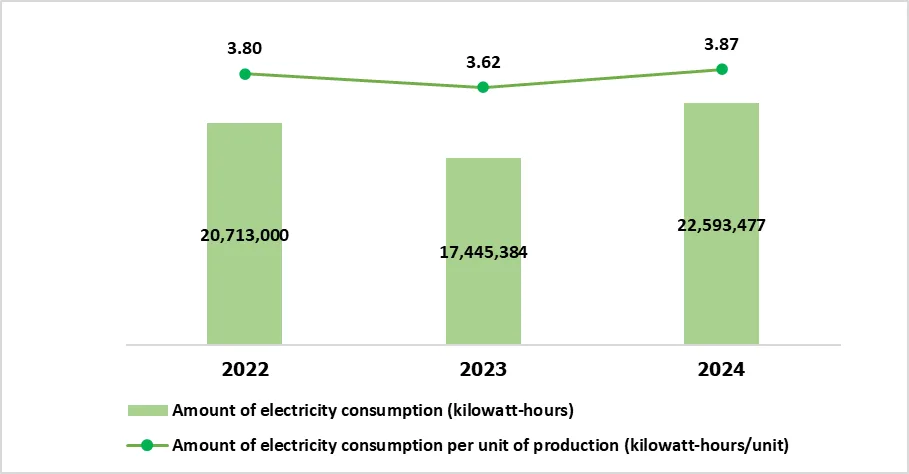

The company has an energy management system in place to achieve the most effective and efficient use of energy. Each year, the company, along with the Environment Management System Committee, sets goals and operates with the aim of reducing electricity consumption. The goals and operations are as follows:

| Target | Base Year | Target Year |

| Reduction of electricity purchased for consumption | 2023: Electricity purchased of 17,445,384.00 kilowatt/hour | 2024: Decreased 3.88% or 16,768,503.10 kilowatt/hour compared to the base year |

The electricity consumption of the company in 2024 compared to 2023 increased by 29.51%. The electricity consumption per production unit increased by 6.95% because in 2024 the production volume was higher than that of 2023 and there were additional machine in the production process. However, the company still has a campaign to reduce energy consumption and increasing leakage rate inspections at various points, such as leakages in the factory’s compressed air. In addition, the company has carried out activities to promote the reduction of electricity consumption as follows

The activities to promote the reduction of electricity

- Changing light bulbs to be energy-saving ones.

- Using renewable energy from the sun by installing a solar power generation system (Solar Rooftop)

- Increase the efficiency of the Air Compressor to replace the old one with low efficiency and install Central Air Compressor.

- Improve the insulation of the wall and door of furnace and improve paint furnace to reduce energy loss

- Reduce the leakage rate of compressed air systems.

| Energy Management: Fuel Usage | 2022 | 2023 | 2024 |

| Diesel fuel (liter) | 35,604.42 | 36,105.26 | 39,514.62 |

| Gasoline (liter) | 4,251.48 | 4,297.43 | 4,716.78 |

| Cooking gas (kg) | 2,920,640.00 | 2,883,940.00 | 3,572,780.00 |

| Total electricity consumption (kilowatt-hour) | 2022 | 2023 | 2024 |

| Total electricity consumption (kilowatt-hour) | 20,713,000.00 | 17,445,384.00 | 22,593,477.00 |

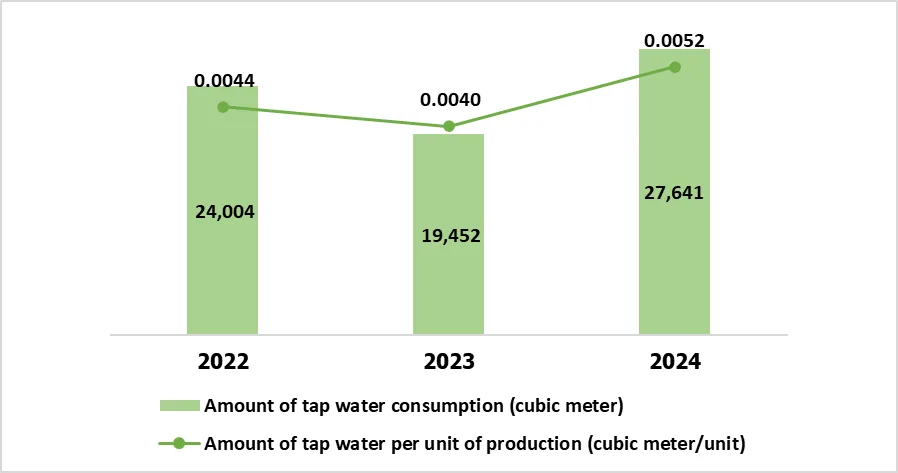

The company manages for efficient water use, by reducing water consumption, and water loss, and managing water quality. Each year, the company and the environmental management system committee have set goals and actions to reduce water usage.

| Target | Base Year | Target Year |

| Reduction of water | 2023 : Water usage 19,452.00 cubic meters | 2024: 5% reduction or 18,479.40 cubic meters compared to the base year. |

The company’s water usage in 2024 compared to 2023 increased by 55.34%. The water usage per production unit increased by 28.36%, with the main factor affecting the increase coming from higher production volume and increasing measures to clean products before export. In addition, water leaks were found. However, the company continue to carry out activities to promote and campaign for reducing water usage. Measures have been added to check for water leaks. The company has implemented activities to promote reducing water usage as follows:

Activities to promote the reduction of tap water usage:

- 100% recycled water used in the production process. The company has treated water with the filterred and disinfected process.

- Expand the amount of water to be able to accommodate more water to be recycled.

- Store rainwater in a reserve pond to be used in the production process.

- Consistently check leakage points of water pipes within the factory to reduce waste.

- Roll out campaign and instill awareness in water usage among employees and increase channels for reporting water leakage.

| Water management: The amount of water usage classified by source of water | 2022 | 2023 | 2024 |

| Total water consumption (cubic meter) | 24,004.00 | 19,452.00 | 27,640.57 |

| Amount of tap water used or water from other organizations (cubic meter) | 12,888.00 | 10,132.00 | 14,632.57 |

| Amount of water used from the production process (cubic meter) | 11,116.00 | 9,320.00 | 13,008.00 |

| Water management: The amount of water used by the company | 2022 | 2023 | 2024 |

| Net water consumption (cubic meter) | 24,004.00 | 19,452.00 | 27,640.57 |

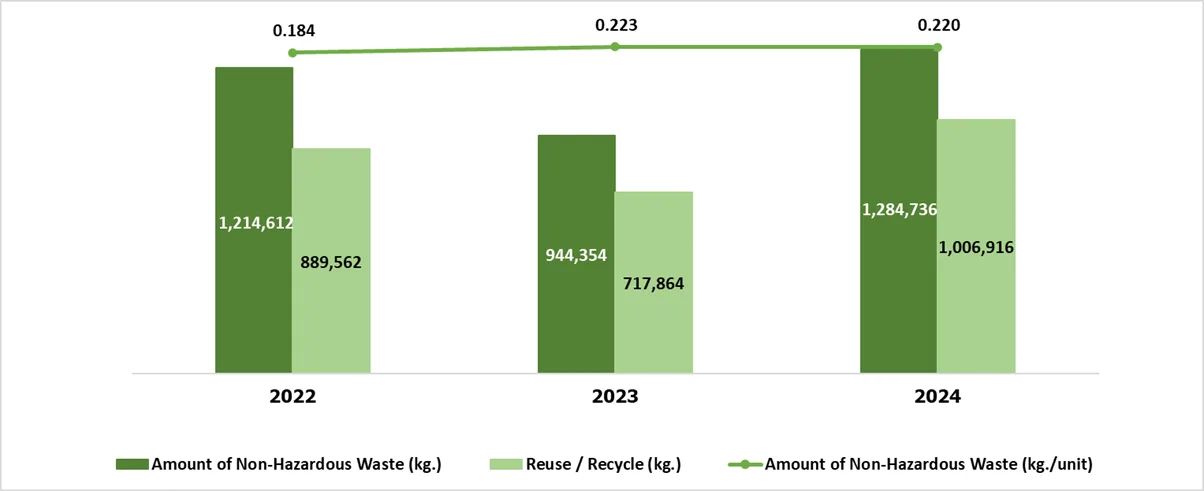

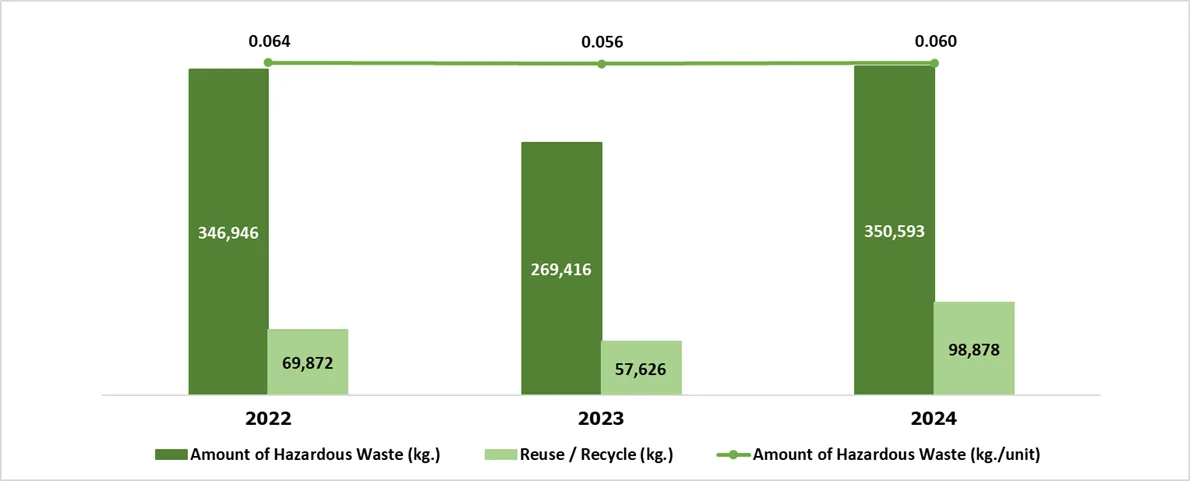

The company has managed garbage and waste both hazardous and non-hazardous. The company has promoted waste management and separation. There is information on garbage and waste management operations as follows.

| Target(s) | Base year(s) | Target year(s) | Waste management methods |

| Reduction of waste generation Waste type: Non- hazardous waste | 2023 : non-hazardous waste 944,353.64 Kilograms | 2024 : Reduced by 0% or 1,181,256.11 Kilograms in comparison to the base year | • Other : Hire an external specialist company for elimination |

| Reduction of waste generation Waste type: Hazardous waste | 2023 : hazardous waste 269,416.00 Kilograms | 2024 : Reduced by 0% or 518,933.00 Kilograms in comparison to the base year | • Other : Hire an external specialist company for elimination |

Remark : (1) – The target for non-hazardous waste in 2024, measured per unit, remains the same as in 2023 since the previous target has not yet been achieved. However, the total volume is expected to increase due to the projected rise in sales for 2024.

– The target for hazardous waste in 2024 is set to increase in total volume as the per-unit target has been raised. This adjustment reflects the company’s efforts to expand the scope of its waste management goals, along with the anticipated increase in sales for 2024.

In 2024, 78% of garbage and non-hazardous waste is utilized by recycling. For the hazardous waste, the company has installed a zinc dust collector box in the production line. This makes it 28% reusable and recyclable.

Activities to promote garbage and waste management:

- The company has provided suitable waste containers, ensuring waste is separated and stored in an organized manner.

- The company has built a contaminated waste shed and disposed of with a standardized company when there is an appropriate amount.

- The company has implemented the “Waste Bank Project” as part of the company’s 5S activities, which the company has continued to implement the project. All employees in the company participated in this activity.

| Garbage and waste management: The amount of garbage and waste of the company. | 2022 | 2023 | 2024 |

| Total amount of garbage and waste (kilograms) | 1,561,557.50 | 1,213,769.64 | 1,635,329.35 |

| Total amount of trash and non-hazardous waste (kilograms) | 1,214,611.50 | 944,353.64 | 1,284,736.35 |

| Total amount of trash and hazardous waste (kilograms) | 346,946.00 | 269,416.00 | 350,593.00 |

| Garbage and waste management: The amount of garbage and waste that is reused and recycled of the company | 2022 | 2023 | 2024 |

| Total amount of garbage and waste that is reused and recycled (Kilograms) | 959,433.50 | 775,489.64 | 1,105,794.35 |

| Amount of trash and non-hazardous waste that is reused and recycled (kilograms) | 889,561.50 | 717,863.64 | 1,006,916.35 |

| Amount of trash and hazardous waste that is reused and recycled (kilograms) | 69,872.00 | 57,626.00 | 98,878.00 |

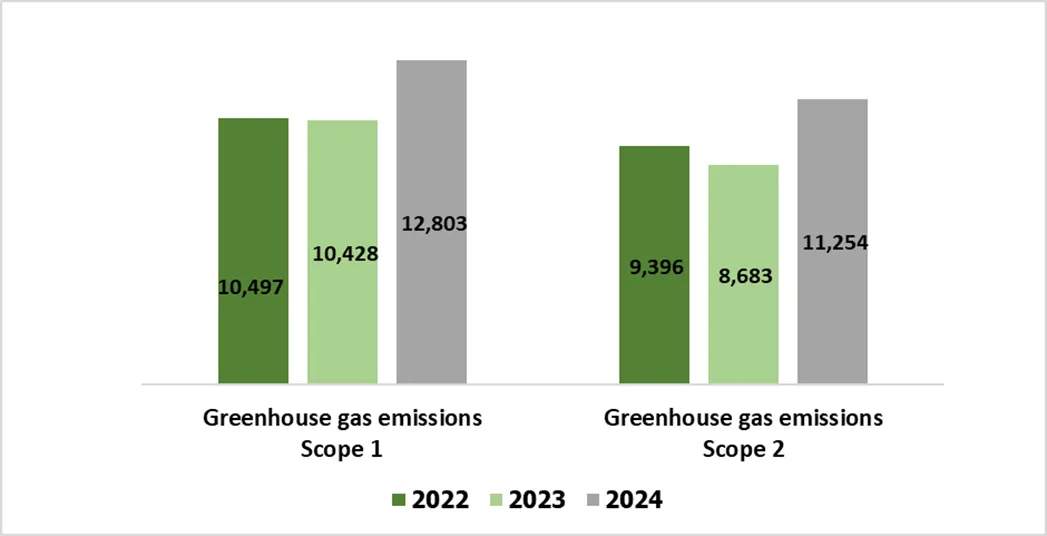

The company realizes the importance of climate change and global warming. Risks from climate change affects the company’s business operations. The company therefore places importance on reducing greenhouse gas emissions, in response to government and private sector policies both domestically and internationally that focuses on reducing greenhouse gas emissions. The company has established a working team of carbon footprint management, conducting an assessment of the company’s greenhouse gas emissions. By setting the year 2021 as the base year. There were a data verification process, data storage, and the measure of the amount of greenhouse gas emissions to a standard. In 2024, the company has hired ECEE Company Limited to be a verifier of the organization’s greenhouse gas emissions. This was the information between 1 January 2023 and 31 December 2023. The company was certified Carbon Footprint for Organization from Thailand Greenhouse Gas Management Organization (Public Organization).

Principles and standards for managing greenhouse gases or climate change: Thailand Greenhouse Gas Management Organization (TGO)

| Emission scope of greenhouse gases | Base Year | Target Year for Short Term | Target Year for Long Term |

| Scope 1 | 2023 : Greenhouse gas emissions 10,428.00 tCO2e | 2024: Reduced 1.88% or 194.13 tCO2e compared to the base year. | – : compared to the base year N/A tCO2e vs base year |

| Scope 2 | 2023 : Greenhouse gas emissions 8,683.00 tCO2e | 2024: Reduced by 0.37% or 35.13 tCO2e compared to the base year. |

1. Direct greenhouse gas emissions (Scope 1):

Caused by the combustion of various fuels, both from machines and from company-owned vehicles such as combustion from the use of LPG, gasoline and diesel, etc. It is also from Carbon dioxide emissions from the production process, use of refrigerants and the use of chemicals in the wastewater treatment system.

2. Indirect greenhouse gas emissions from energy use (Scope 2):

Caused by using the company’s electricity.

In 2024, the company has set a goal to reduce greenhouse gas emissions by 2.25 percent compared to 2023. In 2024, the company emitted a total of 24,057 tons of carbon dioxide equivalent or an increase of 25.88 percent compared to 2023, mainly due to increased electricity usage. The company increased in production volume and the additional of machines in the production process. However, the company still committed to continuously reduce greenhouse gas emissions. There are plans to improve machinery in the production process to be more efficient and reduce energy consumption to achieve the goal of reducing greenhouse gas emissions in the future.

| Management to reduce greenhouse gas problems: amount of greenhouse gas emissions | 2022 | 2023 | 2024 |

| Total amount of greenhouse gas emissions (Tons of carbon dioxide equivalent) | 19,893.00 | 19,111.00 | 24,057.00 |

| Greenhouse gas emissions – Scope 1 (Tons of carbon dioxide equivalent) | 10,497.00 | 10,428.00 | 12,803.00 |

| Greenhouse gas emissions – Scope 2 (Tons of carbon dioxide equivalent) | 9,396.00 | 8,683.00 | 11,254.00 |

Verification of the company’s greenhouse gas emissions: Yes

List of agencies that verify greenhouse gas emissions data: ECEE Company Ltd.

The company has controlled the rate of exhaust fumes accordance with standards specified by law. Each year, the company and the Environment Management System Committee have set targets and have implemented air pollution management. The goals and operations are as follows.

Target: Pass the criteria for measuring the amount of pollutants released from the chimney as required by law.

Measurement results: Passed the criteria

Performance and results of air quality management

Activities to promote air quality management:

- SMPC decreases the dust internally before releasing the air out to the community around the factory, by having the outsource company to bring the vacuum cleaner to daily vacuum in the plant.

- The wet scrubber system is used in the production process. So that the fumes and dust generated by the production process are not emitted into the air, hence less effect to the environment.

- The related departments regularly monitor the quality of air, also have audit and maintenance plan for the machinery and equipment.

- Measures to check the water curtain, water spray and dust filter of the Wet Scrubber.

The company measures noise, light and heat levels to ensure a good working environment for employees and operators. The company also prioritizes the safety and well-being of operators by setting operational goals as follows:

- Level of noise: SMPC consistently monitors level of noise according to the required law to ensure of no noise pollution to the community. Wind noise reduction devices (Silencers) is used in the production process. The company also installed soundproof wall, noise barrier tunnel, soundproof room for grinding, a cover room for water and powder spraying blower, cover room for Zinc and sandblasting blower to reduce noise caused by the factory operation. Planting trees around the factory fence is used as a soundproof wall. SMPC also considers other additional directions to prevent and manage the noise pollution in order not to affect the health of employees in the factory as well as communities in nearby areas. For the employee, the company also have noise protection, such as ear plug, and ear muff for the employees who work in the environment at risk of noise pollution. The employees also are encouraged to wear personal protection equipment (PPE). The company organizes to have the hearing test on top of the annual medical checkup, for the employees who work in the loudly noise area.

- Lighting: The company manages to have the illumination measurement in the working area at least once a year, so that employees get to work with enough lighting, good working environment. This also to prevent accident while working.

- Heat: SMPC arranges the heat measurement in the working area, and immediately correct it, if the hot environment is found to be in improper operation, for example, installing a large ventilation fan, and a screen to block heat radiation from the furnace. There is also a project to drink cool herbal water that helps reduce body heat for employees during the summer.

Employee Education and Training on Environment

The company has a policy to raise awareness and spread the concept of efficient resource utilization and environmental conservation to all employees through training, the company’s notice board, and posters. Additionally, the company organizes activities to inspire all employees to properly use resources and conserve the environment, as follows:

1. ISO 14001 training is provided to new staff members. The public relations team of the ISO 14001 project has already incorporated the project into the annual training course for review.

2. A campaign is being implemented by the company to separate waste into general waste, recyclable waste, and hazardous waste, with continuous efforts.

3. Energy conservation is promoted both within and outside the organization, reaching out to business partners and the community through brochures, contact manuals, and regulations.

4. The company provides a complaint center for submitting complaints related to environmental impact. The center can be reached at 02-895-4139 or via email at em@smpcplc.com, available 24 hours a day.

5. During the quarterly Board of Directors meeting, there will be an agenda item to regularly consider, follow up on, and take action regarding whistleblowing incidents.